Larson says performance marketing is rapidly replacing relationship marketing. EMS providers and OEMs recognize committed inventory heavily buffered by uncommitted inventory. Semiconductor chips will continue to address increasingly specific needs of customers. Market forces putting severe competitive pressures on local distributors forcing re-analysis of business models.

Looking back to 1976, with just 14 employees and $800,000 in sales, Mark Larson assumed management of Digi-Key (www.digikey.com). Back then, no one could have predicted what would happen or that Digi-Key would one day find itself on a trajectory as one of the world’s fastest growing distributors of electronics components.

Fast-forward to 2010. As Company president, CFO and COO, sales at Digi-Key under Larson’s leadership are projected to grow to nearly $1,400,000,000 this year with employment figures nearing 2,200 employees.

No one can doubt Larson’s ingenuity. In his office, perched behind his desk, is a plaque that reads:

People can be divided into 3 basic groups:

- Those who make things happen

- Those who watch things happen

- Those who wonder what happened

Mark Larson has leveraged technology and, in a very real sense, redefined distribution for electronics components by successfully developing and implementing strategies that have uniquely positioned Digi-Key in the electronics distribution industry.

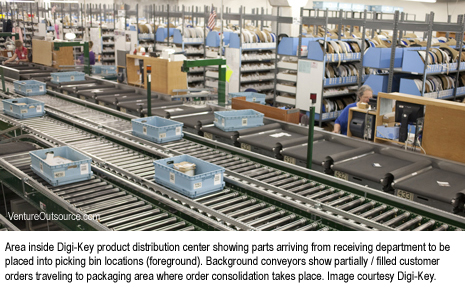

Today, Digi-Key derives more than 75% of its sales from the Internet, all from one 600,000 square-foot product distribution center located in Thief River Falls, Minnesota.

The power of this ‘redefinition of distribution’ is clearly substantiated by the performance of Digi-Key relative to its peers. In North America, this performance has resulted in the Company’s rise from being the 20th to becoming the 4th largest electronics components distributor in six years.

Worldwide, Digi-Key has risen from becoming the 11th largest to the 8th largest distributor in the past several years.

What’s remarkable about Digi-Key is the Company’s growth has all been organic, without any acquisitions.

VentureOutsource.com talks with Mark Larson about his Company’s rise and plans for the future. Read what Larson says about why Digi-Key has not regionalized like other electronics components distributors; how Digi-Key has leveraged technology, the wonders of performance marketing, counterfeit components, semiconductor industry trends, and more.

Transcripts from that discussion follow…

VentureOutsource.com: Can you tell our readers what important leadership lessons you’ve learned?

Larson: The single most important leadership lesson I have learned is the importance of thoughtfully developing, communicating and implementing a corporate vision. In the earliest days of Digi-Key, we had a very small number of employees and this process occurred almost without trying.

As we have grown, employee functions have become more narrowly defined. This is good to the extent that they are able to become more focused and develop a deeper knowledge of their area of responsibility. However, it can inhibit their ability to understand the business in a broader sense. As a consequence, it’s critical that we now formally communicate the corporate vision and provide the rationale and goals in sufficient detail so we are all on the same page.

VentureOutsource.com: How has your leadership style changed over the years?

Larson: As COO of Digi-Key for the past 34-years, I would like to think that my leadership style has changed, or at least become slightly more polished.

The biggest driver of any change has been the growth of the business and the need to delegate both responsibility and authority.

This business has never been a one-man show, and that is even more true today.

But, in the early years my involvement was deeper in all areas of the company and on that basis I logically made many more decisions.

We now have a strong and cohesive management team with expertise in many areas far beyond my own and they are pushing us forward and working to implement programs that will strengthen Digi-Key in terms of both operations and marketing.

My style has changed to become more of a facilitator and much less of an implementer in helping the team members achieve their goals.

I admit it’s been challenging to avoid micromanaging some of these initiatives, but I do my best.

VentureOutsource.com: What’s the basic message you have for all of your employees?

Larson: Although it may sound trite, in its simplest form my message to Digi-Key employees is that we are here to serve our customers and that our goal is not to be the biggest electronics components distributor in the world, but to be the best electronics components distributor in the world.

Of course, I silently hold the belief that if customers see us as the best we might ultimately become the biggest.

VentureOutsource.com: Can you please share with our readers some of the contributing factors you feel why a single-source location strategy has worked well for Digi-Key and still makes sense compared to regional expansion strategies being executed by your competitors?

Larson: Electronic components typically have a relatively high value-to-weight ratio that allows them to be shipped cost-effectively from country-to-country and region-to-region throughout the world. Free trade agreements exist in almost all major markets, which further facilitate worldwide sourcing.

Additionally, UPS and FedEX deliver quickly…worldwide. We can deliver product almost anywhere in the world within two to three days.

Digi-Key is unique among major distributors because all orders processed are shipped from our sole product distribution center in the United States. This means we can stock inventory based on the aggregate usage from all regions in the world rather than stock based on the more limited sales activity in any single region.

This allows us to economically justify stocking the broadest range of board level components in the world.

We can also justify stocking in great depth. This strongly plays to the advantage of Digi-Key customers for both engineering and production needs. Validation of this concept is our exponential sales growth in Europe, Asia and the world.

VentureOutsource.com: What are some of the different types of challenges you are seeing in electronics supply chain distribution models in today’s environment?

Larson: The rapid upturn in demand has revealed the greatest weakness in the highly focused supply chain distribution models.

The fact is that industry and world economic conditions are difficult and impossible to predict.

In a perfect world, Mark, an EMS provider or OEM would establish production schedules and never revise them. In that type of world, the supply chain distribution model is the perfect solution.

In the real world, production schedules must change to meet changing demands of a specific product or adjust to rapidly changing industry or world economic conditions.

Supply chain distribution must be a significant component of its business and it is growing rapidly. The reason it is growing rapidly is that EMS providers and OEMs recognize that the committed inventory that supports Digi-Key’s supply chain business is heavily buffered by uncommitted inventory that is available for immediate off-the-shelf delivery.

This means that if there is an unanticipated increase in demand, we are typically far more capable of quickly adjusting to increased quantities on production schedules and meeting the needs of the customer than traditional distributors.

The fact that Digi-Key is growing twice as fast as traditional distributors confirms the industry need for a distributor that is not purely focused on inventory turns and ROI.

In your search results you can further target other Industries and/or Services plus, you can add more geographies to your search.

VentureOutsource.com: Looking at traditional supplier / distributor relationships and management techniques, how do you see these relationships and management techniques changing as the distribution industry undergoes further changes?

Larson: I believe the single biggest change that is occurring in electronic component distribution, and most other industries, is the rise of performance marketing at the expense of relationship marketing.

Relationship marketing implies that a purchase is based on interpersonal or business relationships.

In the real world, although relationships alone are not typically the sole factor in making a business decision, they have often had a strong impact on purchasing decisions and would skew a decision to the disadvantage of the purchaser.

This was understandable since in the past a professional purchaser or buyer of components for production quantities was formerly forced to rely on a distributor sales representative for product availability; pricing, lead-times, possible substitutions and tracking shipments.

This dependency is broken today.

Digi-Key’s Website gives the purchaser instant access to this information and far more. Many customers have elected to control their own production schedules by utilizing a customized version of Digi-Key’s virtual in-house store.

In addition, we process millions of quotes a year for volume purchasers. For purchasers of production quantities that require or desire a single point of contact, our volume business division representatives are prepared to work with them on both daily sourcing issues as well as scheduled releases.

Performance marketing is rapidly replacing relationship marketing. The distributor that consistently performs is the one that earns the business.

VentureOutsource.com: What are some purchasing trends Digi-Key is seeing develop with regards to components and semiconductors?

Larson: A dominant trend that continues to gain momentum is worldwide sourcing of components by EMS providers, OEMs and engineers.

Historically, world markets have been served independently with a distributor locating warehouses in many countries and regions throughout the world. It was, and is, inefficient but in the past was necessitated by the limitations of communication and logistics.

Today, however, communication is instant. And in terms of getting the product from point A to point B in the world, logistics can consistently and cost effectively move product in a matter of several days.

It’s a new world, a new way of doing business.

VentureOutsource.com: Looking out five years, how do you see progressions with technology impacting the semiconductor business? How might these changes impact Digi-Key’s business?

Larson: It is probable that the functionality of semiconductor chips will continue to address increasingly specific needs of a given customer. On this basis, the customer will be able to choose from an increasingly wider selection of product and select a device that is truly solution-specific.

This proliferation of product will require a distributor with an extremely broad and deep reach into the design community. Digi-Key is clearly the dominant player in this respect.

Get your list of EMS manufacturers (Its free)

Save time and money. Find quality EMS manufacturers. Fast. Venture Outsource has a massive, global database of contract electronic design and manufacturing capabilities. Speak with a Provider Advisor.

“Was able to very quickly find details on the important elements of setting up EMS and ODM partnerships, talked with an advisor for personalized info on quality providers matching our requirements while getting up to speed quickly about the industry and connect with key staff from like-minded companies and potential partners. Great resource.”

— Jeff Treuhaft, Sr. Vice President, Fusion-IO

Advisors tell you matches we find for your needs, answer your questions and, can share EMS industry knowledge specific to your industries and markets.